Mining & Industrial

Projects Revitalised

Why accept anything less than excellence in your industrial projects and mining operations? Become part of the elite league of industry pioneers who’ve harnessed the game-changing prowess of Fluid Systems. Reach out to us now to delve deeper into how we can partner with you to unleash unparalleled efficiency, productivity, and cost-saving advantages in your mining and industrial ventures.

Tailored Solutions By Fluid Systems

Mining Solutions

Custom Industrial Solutions

Enhanced Productivity and OPEX Savings

Fluid Systems understands the critical importance of productivity in the mining and industrial industries. Our tailored solutions are specifically designed to unlock your operation’s full potential. By leveraging advanced automation, improved technology, and custom solutions, we empower you to identify bottlenecks, optimise workflows, and increase productivity. From ore extraction to processing and transportation, Fluid Systems enhances productivity at every step of the value chain.

Fluid Systems is committed to helping mining and industrial operations achieve substantial operational expenditure (OPEX) savings. By employing cutting-edge technologies and strategic optimization approaches, we identify opportunities for cost reduction without compromising performance or safety. Our comprehensive solutions optimize energy consumption, reduce water usage, minimize waste generation, and enhance equipment lifespan, resulting in significant OPEX savings over the long term.

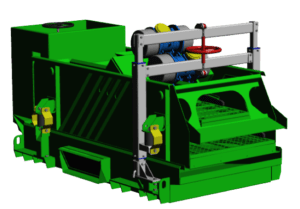

The Latest FSI Tech For Mining

Hi-E™ Technology

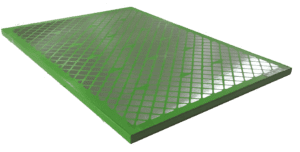

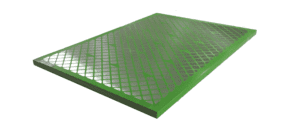

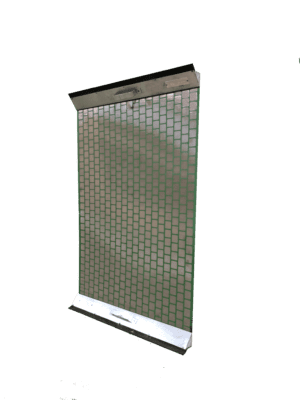

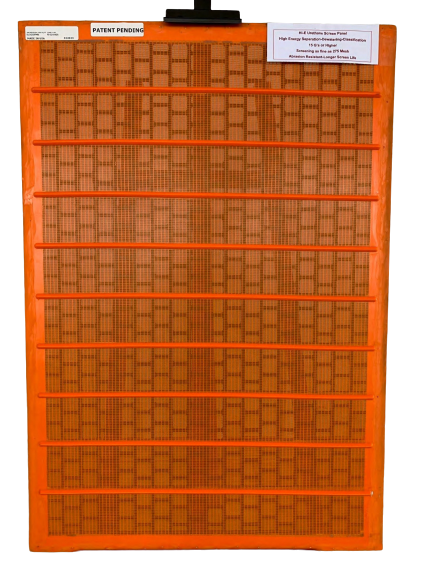

Hi-E™ Urethane Screen Panels

Fluid Systems Hi-E™ urethane panels are the results of an intensive R&D program. This technology has been developed to process abrasive materials at high processing rates. Our urethane panels are designed to deliver high performance with our Hi-E™ technology at 15 G’s or more.

The Difference

- High performance

- Increased processing capacity

- Hi-E™ Technology

- 15 G’s or more

- Light frame design

- High Energy Separation-Dewatering-Classification

- Screening as fine as 230 Mesh (63 microns)

- Resistant to near size particle blinding

- Use Hi-E™ for challenging applications:

– Finer cut points

– High efficiency (up to 99%)

– Higher processing capacities than conventional screens

– Dryer product in dewatering applications

- Patent pending

Available Equipment

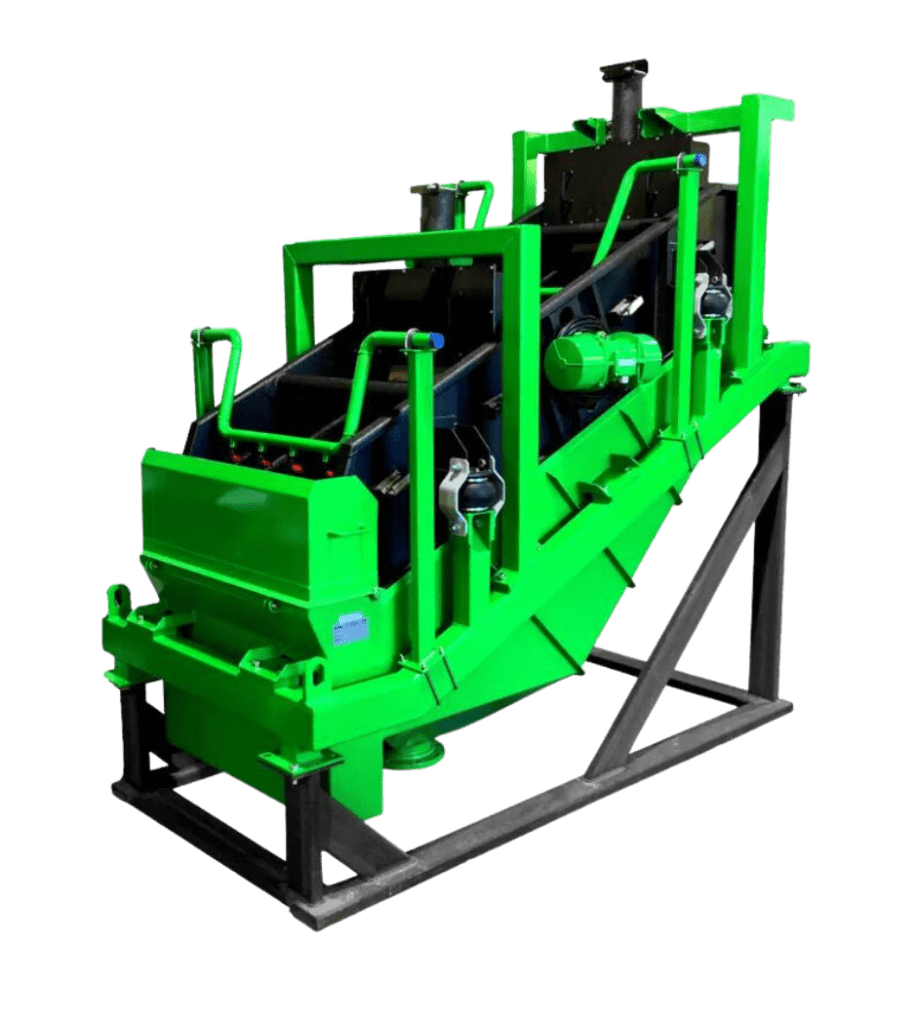

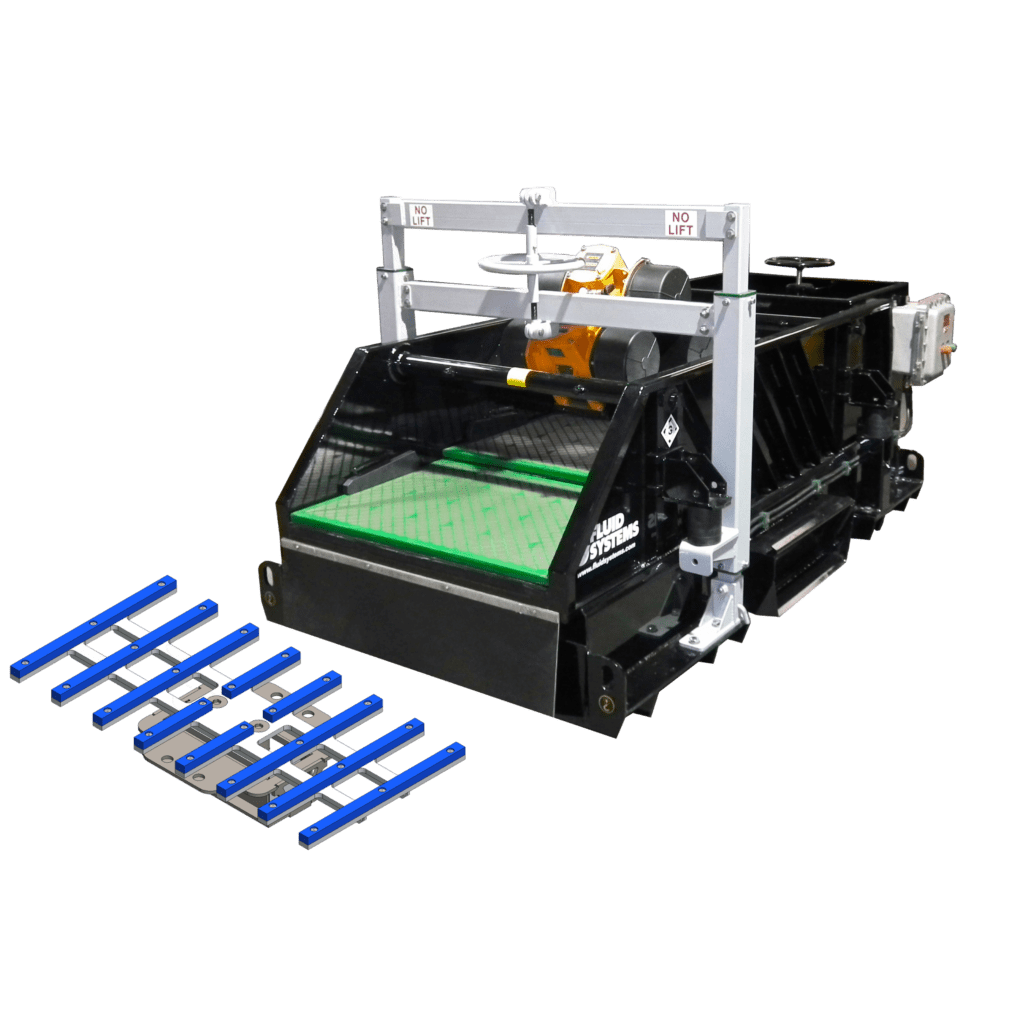

Mining Equipment

-

Series 3642 DFL

View Details -

Series 3642 RPU

View Details -

Series 4224-96

View Details -

Series 5000 Cascade

View Details -

Series 6000 Model B4Z SSL Shaker

View Details -

Series 5111 Model BTHS Shaker

View Details -

Series 3642RPU-18Z Shaker

View Details -

Series 2L Model Linear motion shaker

View Details -

Series 20L Model Double Deck Shaker

View Details -

3XF-FSI Folded Frame

View Details -

Brandt VSM Screen Panel

View Details -

Derrick® 500 Screen Panel

View Details

Industrial Equipment

-

Series 3642 DFL

View Details -

Series 3642 RPU

View Details -

Series 4224-96

View Details -

Series 5000 Cascade

View Details -

Shaker & Mud Cleaner Skid

View Details -

Series 6000 Model B4Z SSL Shaker

View Details -

Series 5111 Model BTHS Shaker

View Details -

Series 3642RPU-18Z Shaker

View Details -

Series 2L Model Linear motion shaker

View Details -

Series 20L Model Double Deck Shaker

View Details -

3XF-FSI Folded Frame

View Details -

Brandt VSM Screen Panel

View Details

Download the Complete Fluid Systems, Inc. Catalog

Enter your email address below to browse the entire catalog of Solids Control & Waste Management equipment.