50% MORE THROUGHPUT. 20% DRIER PRODUCT. LOWER SCREEN COSTS.

CHANGE THE GAME WITH Hi-E™ SCREENING

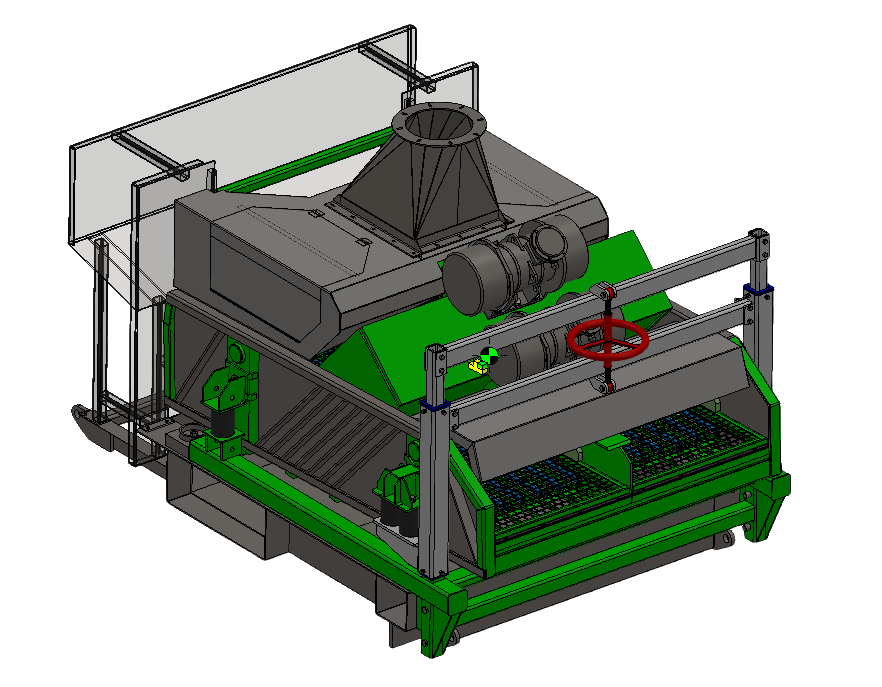

Fluid Systems’ Hi-E™ technology sets a new industry benchmark for oil & gas, mining and industrial applications superior performance, cost savings, and operational flexibility. Engineered for the toughest environments, our Hi-E™ machines deliver G-forces unmatched by any competitor. Increase throughput up to 50%, empowering you to drill faster, recover more fluid, and enhance separation efficiency.

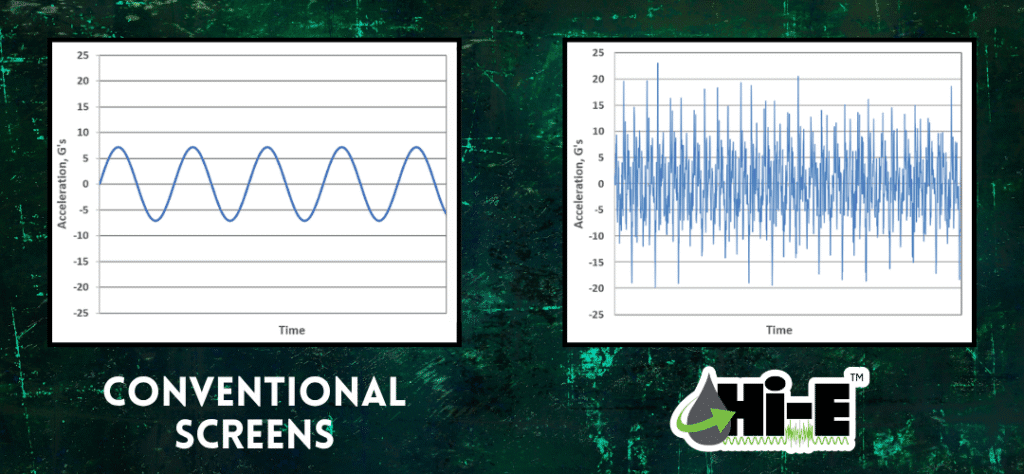

What truly sets Hi-E™ apart is its ability to operate at G-forces of up to 15 G’s, more than double the typical 5–7 G’s delivered by standard competitor machines. Experience up to a 50% increase in throughput tonnage on Hi-E capable machines with screen panels resistant to screen blinding. This remarkable increase in processing capacity is made possible by Hi-E’s advanced design, which features a robust linear motion mechanism that maintains high efficiency and reliability under heavy loads.

Fluid Systems’ Hi-E™ machines produce solids that are 15–20% drier than conventional systems. Alongside 80–90% solids content, this drastically reduces waste handling, transportation, and disposal costs in oil & gas applications. Operators can save up to $150,000 annually on waste costs and over $2 million per year in fluid recovery for high-volume operations, while benefiting from increased throughput and improved sustainability.

Fluid Systems’ Hi-E™ Replace-A-Bed™ program allows users to refurbish existing machines, including major competitors, at a fraction of the cost. This upgrade is minimally invasive and delivers significant operational savings through higher G-forces, increased processing capacity up to 50%, improved fluid recovery, and fewer screen panel changes.

Fluid Systems’ Hi-E™ urethane screens are engineered for high-capacity, high-G-force mining and industrial applications, delivering up to 50% higher throughput than conventional panels and consistently producing stackable solids with up to 90% solids content. Lightweight, durable frames make them resistant to screen blinding, reducing unscheduled downtime and lowering maintenance costs.

50% MORE THROUGHPUT. 20% DRIER PRODUCT. LOWER SCREEN COSTS.

Fluid Systems’ Hi-E™ screening change the game in industrial screening by delivering up to 15+ G-forces, tailored to meet the demands of oil & gas, minerals processing, waste management and other high-throughput applications. Customize your machine’s G-forces to match your material handling needs.

Users can expect up to 50% higher processing capacity compared to conventional systems. Engineered for the toughest drilling environments, our Hi-E™ screens and shakers deliver unmatched G-forces, processing capacity, and screen longevity, empowering you to drill faster, recover more fluid, and reduce waste in oil & gas applications.

Hi-E™ machines achieve 10–15 G’s, far surpassing conventional machines that typically achieve about 7G’s. This results in drier solids, up to 20% drier than competitive equipment, and a significant reduction in drilling timein oil & gas applications.

G-FORCE COMPARISON

FLUID SYSTEMS SERIES 5111 HI-E™ SHAKER VS DERRICK® HYPERPOOL®

Test results prove that Fluid Systems’ Hi-E™ shaker with customizable 10–15 G-forces delivers greater separation and conveyance performance than conventional Derrick® Hyperpool shakers. Fluid Systems’ 5111 Hi-E™ shaker was able to process 50% more volume with a 33% reduction in ROC (Retention on Cuttings). Hi-E™ also allows for higher throughput with fewer screen changes.

Customers using Hi-E™ are estimated to see $50,000 in savings per well on screen panels, transportation, disposal and dilution costs.

Implementing Hi-E Shakers offers these benefits:

- 50% more volume compared to the Derrick Hyperpool shakers

- Up to 33% reduction on retention on cuttings

- Screen panels cost lowered by 50%

- Rig haul-off decreased by 30%

- Dilution lowered by 40%

- Savings with the Hi-E are estimated in $50,000 per well on screen panels, transportation, disposal, and dilution costs

- Increased rates of penetration (ROP)

Fluid Systems 5111 Hi-E™: 15 G’s

400 GPM, API 170 screen panels

Derrick® Hyperpool®: 8 G’s

400 GPM, API 170 screen panels

REDUCE MOISTURE CONTENT 20–30%

Achieve 80-90% solids content and drastically reduce downstream.

Fluid Systems’ Hi-E™ technology is engineered to significantly lower moisture content, directly reducing the costs associated with waste handling, disposal, and water recovery. By delivering customizable G-forces of 15 or higher and leveraging proprietary urethane screen panels, Hi-E™ systems achieve solids that are 15–20% drier than those produced by conventional equipment.

The impact on operational costs is substantial: lower moisture content means maximize mineral recovery and prevent water waste. Field data demonstrates that users can realize annual savings in dewatering, filtration, and thickening operations.

By choosing Hi-E™, users benefit from measurable reductions in moisture content, lower total cost of ownership, and improved sustainability across mining, industrial, and oil & gas applications.

REPLACE-A-BED™ PROGRAM: OPEX SAVINGS WITH MACHINE BED REFITTING

Fluid Systems’ Hi-E™ Replace-A-Bed™ program offers the ability to upgrade current Fluid Systems shakers, as well as the Brandt King Cobra, King Cobra Venom, VSM 300 and M-I Swaco Mongoose shakers, at a fraction of the cost required with a new machine.

Our Hi-E™ Replace-A-Bed™ systems can be installed with minimum cutting and welding and without changing the flow line and manifold. In no time, your machines’ capacity can be increased up to 50% over competitive equipment, with lower ROC and longer screen life.

Why Replace-A-Bed™?

- High G-Force Technology: 10 – 15 G’s

- Increased processing capacity up to 50% over competitive equipment

- Linear / Balanced elliptical motion

- Improved drilling fluid recovery

- Lower Retention on Cuttings (ROC), up to 30% over conventional shakers

- FSI 3XF screens offer up to 50% longer screen life compared to conventional panels

- Quick change of screen panels

- Low maintenance cost

- Low noise (< 75 dBA)

- API RP 13C (ISO 13501) compliant

Hi-E™ Replace-A-Bed™ is available for:

Fluid Systems and its products indicated by trademark symbols are trademarks and/or registered trademarks of Fluid Systems, Inc.

Derrick are trademarks and/or registered trademarks of Derrick Corporation.

NOV, BRANDT, KING COBRA and VSM 300 are trademarks and/or registered trademarks of National Oilwell Varco.

M-I SWACO, Mongoose, and Meerkat are trademarks and/or registered trademarks of M-I L.L.C.

NO BLINDING, LESS DOWNTIME WITH FLUID SYSTEMS LINE OF HI-E™ URETHANE SCREENS

These panels are engineered specifically for high-capacity, high-G-force applications, delivering reliable performance even with the most abrasive materials and demanding throughput requirements.

Manufactured from proprietary urethane blends, Hi-E™ panels are built to withstand abrasive slurries and aggressive process conditions typical in mining and industrial plants. Designed to operate seamlessly with Fluid Systems’ Hi-E™ screening machines at G-forces of 15 or higher, ensuring superior separation, dewatering, and classification performance. Achieve separations as fine as 230 mesh (63 microns) with up to 99% efficiency, ideal for applications requiring precise particle size control and minimal losses.

Increased Processing Capacity: Up to 50% higher throughput compared to conventional screen panels.

Drier Product, Lower Moisture: These panels consistently produce stackable solids with up to 90% solids content, reducing downstream handling and disposal costs.

Lightweight, Durable Frame: Light-frame design minimizes flexing, maximizes energy transfer from the Hi-E machine, and extends screen life, resulting in lower maintenance and replacement costs.

Resistant to Screen Blinding: Specially formulated to resist near-size particle blinding, maintaining high efficiency and reducing unscheduled downtime.

Patent Pending Innovation: Hi-E™ Urethane Panels incorporate Fluid Systems’ latest advances in screening technology, with several unique features currently patent pending.

HI-E™ BY FLUID SYSTEMS: THE NEW STANDARD FOR INDUSTRIAL SCREENING PERFORMANCE.

Contact Fluid Systems to discuss your application and see how Hi-E™ technology can deliver measurable improvements in throughput, product quality, and cost savings.