New Technology

We provide equipment to many process industry customers and work with new applications to improve product quality and output. Look to Fluid Systems to introduce new models and technology year after year.

The BARKEEPER™

- • Small Footprint

• Low CAPEX - • Low OPEX

• Low Maintenance

The BARKEEPER™ is a patented centrifugal separator designed to process weighted drilling fluids at the highest possible rates and with maximum efficiency. The BARKEEPER™ recovers as much as 100% of the barite in weighted drilling fluids. The barite is returned to the active mud system, while decanting centrifuges can be used to discard the low gravity drill solids.

A dual gradient, deep water drilling system based on dilution of riser mud requires economically separating the riser mud into a low-density dilution fluid and a higher density drilling fluid. The BARKEEPER™ can be used in combination of 250 GPM/ 925 LPM modules to achieve economical separation of the mud into low density and high density streams with superior rheological properties as compared to centrifuges.

Multi G

- • Variable G-Forces: 10 – 50 G’s

• Multi-Frequency [30 Hz up to 1000 Hz]• High Volume

• Linear motion

• 25 ft2 [2.4 m2] Screening Area

• No screen blinding

- • Centrifugal Dryer Alternative

• Less operation and maintenance cost

• Small footprint

• No lubrication

• Low noise ( < 80 dB)

• Low energy consumption

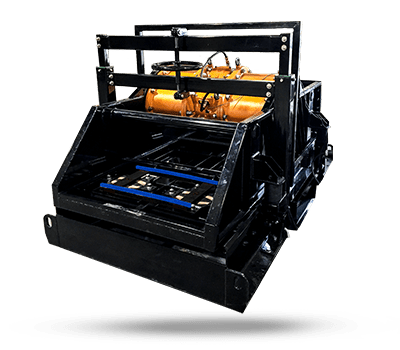

Introducing the MultiG™ Cuttings Dryer, FSI’s latest advance in high “G” force, high volume, linear motion drying shaker. This technology works on the principle of resonance; exciters located underneath the screen panels use the vibrator motors frequency to convert single-frequency oscillations into MULTI-FREQUENCY motion. The energy generated on the exciter is then transferred to the screen panel.

FSI has designed this unit to achieve up to 50 G’s. The shaker was first designed as a drying shaker but it can also be used as a fowline shaker or mud cleaner. Even in the most challenging applications, the MultiG™ achieves consistently high throughput. Processing rates vary with slurry content, percent solids and viscosity.

ProdiG-MG

- • Intelligent Automation

• Motion control

• Conveyance control

• Vibration control

• Multi-Frequency [30Hz up to 1000Hz] - • Remote control operation

• Real time monitoring

• Variable “G”-Forces – 10-50 G’s

• 25 sq ft (2.4 m2) of screening area

• Low Maintenance

Introducing the ProdiG-MG shale shaker, FSI’s latest advance in high “G” force, high volume, linear motion shaker. This technology works on the principle of resonance; exciters located underneath the screen panels use the vibrator motors frequency to convert single-frequency oscillations into MULTI-FREQUENCY motion. The energy generated on the exciter is then transferred to the screen panel.

FSI has designed this unit to achieve up to 50 G’s. The shaker was frst designed as a drying shaker but it can also be used as a fowline shaker or mud cleaner. Even in the most challenging applications, the ProdiG-MG achieves consistently high throughput. Processing rates vary with slurry content, percent solids and viscosity.